Unlocking the power of waste

Maximise biogas production with our next-generation waste-to-energy tech

Maximise biogas production with our next-generation waste-to-energy tech

We build modular plug & play systems that fit seamlessly into your operations. But that’s just the start — as your partners, we’re there every step of the way, maintaining and optimising your equipment to ensure you get the most value from your waste.

Let our AI and biosensors take care of everything 24/7 while you focus on doing what you do best.

Improve your methane yields, double feeding rates, and maximise plant efficiency with round-the-clock insights.

Learn more

Turn your byproducts into bioenergy on-site, reducing wastewater treatment costs and slashing your energy bills.

Learn more

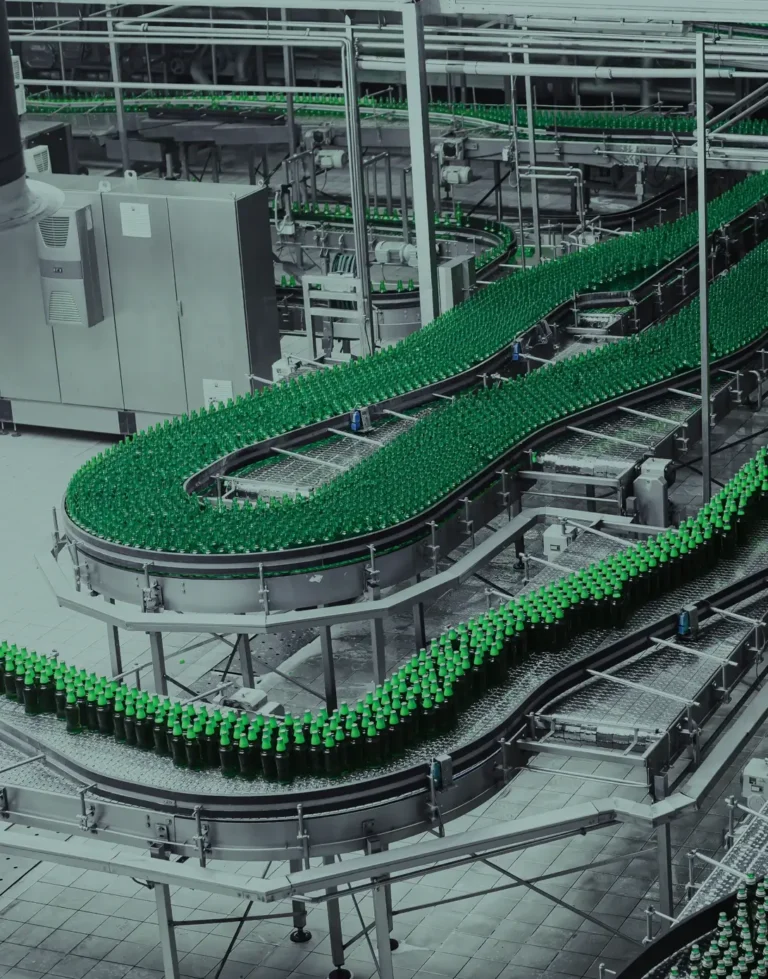

Convert by-products and wastewater into biogas to power your production line and save thousands on treatment.

Learn moreIf you’re interested in finding out more about our technology or how we could work together, we’d love to hear from you.

"*" indicates required fields